It is important for every owner of a private house that his home looks attractive, stands out against the background of neighboring buildings and lasts as long as possible.

That is why today the question of how to sheathe a frame house from the outside is of interest to so many owners. In the modern construction market, a large number of finishing materials are presented, with which you can sheathe a frame house. To choose in all this diversity, you need to take into account the individual characteristics of the structure, your own financial capabilities and preferences.

Facing materials

The rapid development of technology has led to the fact that on the modern market there is a huge number of different claddings that make it possible to cover any houses, be it frame, brick or any other buildings. It is impossible to single out any one type of finish on the market and call it the best, since each type of facing material has its own positive and negative qualities. The best material, the most suitable in individual conditions, each owner has to choose for himself.

wood finish

Wood trim has been used by mankind in construction for many centuries. This is a natural, environmentally friendly material with which you can improve the appearance of any building. Among the shortcomings of natural wood, it is often distinguished by its high cost and poor resistance to various negative impacts.

As an alternative to standard wood siding and boards, a modern outdoor blockhouse can be used.

Block house is an imitation of natural rounded timber, which is processed during the production process with various protective compounds that ensure the resistance of the finish to various negative influences.

A block house is perfect for cladding a frame house from the outside, it improves the thermal insulation characteristics of the building, allows the building structures to "breathe", protects the frame walls from various external influences.

Finish scheme

Finish scheme In addition, block house cladding is easy to install outside the building on your own, this does not require any special knowledge and skills, all the necessary information for self-assembly, can be found in the manufacturer's installation instructions or in the training videos available on the Internet.

Among other advantages of the block house, it can be noted that, although it completely imitates a wooden beam, it does not have the disadvantages that are characteristic of most natural wooden products. Thanks to modern production technologies, the installed block-house panels on a frame house do not crack during operation, and they are much cheaper than natural products. Extremely attractive visual characteristics make it possible to use the block house as an external and internal cladding of various houses. If interior walls are lined with this material, then they will not necessarily be pasted over with wallpaper.

Natural and artificial stone

Modern stone facings are also well suited for cladding frame houses from the outside. Natural stone tiles are distinguished by excellent visual qualities, with its help, you can implement the most aesthetic design projects. The stone on any building will look spectacular, will attract attention and highlight the building against the background of neighboring houses.

A natural stone has excellent technical specifications, such cladding is able to protect the structure from any negative influences, whether it be temperature extremes, ultraviolet radiation, precipitation, mechanical or chemical influences. Installing such a sheathing from the outside can significantly extend the life of any frame house.

Have natural stone for facade decoration from the outside and some shortcomings. The main unpleasant characteristics of stone finishes for owners are its extremely high cost and big weight. The price reduces the number of owners of private houses who can afford such sheathing, as for the large weight, the additional load created by the stone on the supporting structures of the house can be sustained only by the most reliable buildings, most often built recently and in accordance with modern standards and rules. For the reconstruction of many old houses, stone tiles are not suitable precisely because of the large weight. In addition, a lot of weight can significantly complicate the installation of sheathing on the walls of a frame house from the outside. It is quite difficult to install stone cladding on your own, and professional installation services are very expensive.

stone finish

stone finish Fake diamond much better suited for sheathing frame houses from the outside, due to its lower weight. The installation process of artificial stone trim almost completely repeats the installation of facade ceramic tiles. If you have ever faced the task of laying tiles, you can easily install the artificial stone sheathing yourself.

Among other things, modern imitations of natural stone are distinguished by significantly lower cost, a wide variety of colors and textures, excellent thermal insulation properties, and technical characteristics.

Stucco finish at home

Plaster is the most common type of exterior cladding used in Russia and other European countries.

Stucco mixtures have many positive qualities, they are characterized by low cost, a wide range of colors and textures. With their help, you can sheathe the surface of any house from the outside, including a frame structure.

A wide range of plasters on the market gives owners the opportunity to create facades of houses, visual characteristics reminiscent of various natural finishing materials - wood and stone. Depending on the type of plaster mixture, it can contain both standard mineral fillers and acrylic dyes, as well as silicone, and even marble chips, which provide an extremely attractive appearance for a facade lined with such material.

High-quality, modern plaster mixtures have not only high aesthetic properties, they are also characterized by extremely attractive technical parameters for owners. Many plasters are resistant to any external negative influences, do not lose their visual characteristics during operation, even in the most adverse external conditions. If a ahead of time plaster service was no more than 5 years, today, the durability of some products on the market can be several decades.

An important advantage of plaster for cladding frame houses on the outside is also simple installation.. Any owner can decorate his own home with a plaster mixture on his own, this does not require professional knowledge and even experience, everything you need can be learned during the installation process.

A huge selection of finishing materials can confuse rather than really help an inexperienced developer solve the problem with exterior decoration. In this article, we will figure out what important parameters the finishing of a frame house on the outside should correspond to, and we will analyze the materials.

1 General requirements - we determine the main

The main task of the outer skin of a frame house is to protect the entire structure from getting wet and other atmospheric phenomena. The sheathing takes on light mechanical damage, and also protects the insulation layer from moisture and direct sunlight, which is especially important for foam. Therefore, the material for exterior finish must meet a number of mandatory requirements:

- resistance to atmospheric and weather phenomena (wetting, heating, freezing, icing, hail);

- increased strength - the finish should easily withstand mechanical damage that hail, wind, tree branches can cause;

- ability to resist ultraviolet radiation.

When constructing a frame house, the customer can choose almost any method of exterior decoration of the building and basement. This choice depends on several factors:

- budget;

- the climate of the region;

- the material chosen for the insulation of the frame.

Everything is clear with the budget - the more money, the more opportunities. However, expensive exterior decoration of a frame house is not a panacea for problems. On the contrary, sometimes there are even more worries. For example, finishing (imitation of a log house) promises a beautiful appearance, but every few years the material must be treated with paints and varnishes and antiseptics so that the tree retains its strength and beauty. At the same time, a block house costs more than lining or vinyl siding.

The climate of the region depends primarily on what type of finish you choose. For example, if you live in a damp and rainy area, the choice of wood materials is not the best, as you will constantly fight rot. In extremely cold climates, it is best to avoid metal siding - metal conducts heat too well, while wood has a fairly low thermal conductivity.

If you chose to insulate the frame mineral wool, you will no longer be able to use plaster for finishing, unless you stuff plywood or OSB boards over the insulation, which will increase the expenditure. In the case of mineral wool, it is much easier to use lining, siding, block house. But if you chose expanded polystyrene (polystyrene), then you can fully plaster the walls, because plaster can be applied directly to the foam sheets.

2 Advantages and disadvantages of materials - an overview of the best options

Having decided on the budget, climate and material for insulation, it's time to move on to choosing the finish itself. frame houses most associate with wood, hence the frequent choice of wood for decoration. In addition, one of the main arguments in favor of wood is the lightness of the material. However, it is not necessary to emphasize this - if the house is built on a good strip foundation, you can use a heavier finish.

Wooden materials suitable for exterior decoration - lining and block house. Block house, in turn, can imitate both timber and rounded logs. By the way, he does it very well - to understand what kind of material is in front of you, you can only approach directly to the facade. Lining is more affordable, since the production of this material produces much less sawdust and shavings. Block house cannot boast of this quality.

To wood trim the facade of the frame house has served for many years, choose a material that is not too thin, which is sold after a good drying. Another important point is that finishing panels should be laid in a horizontal position, since they can deform over time in a vertical position.

Do not forget to renew the paint layer at least once every five years, and then this finish will serve you for many decades.

- these are wall panels that are equipped with convenient grooves and locks for tight fastening. Metal siding is made of thin sheet steel, which is covered with a whole range of different paints, polymeric protective films and coatings. As a result, the material successfully withstands prolonged exposure to ultraviolet radiation, does not rust, does not fade over time and is not afraid of low and high temperatures. Of course, this is ideal - the quality of metal siding can vary significantly in some cases. If it's just painted metal, don't expect it to last long.

It is possible to mount metal siding both vertically and horizontally; special knowledge and training are not needed to work with it. Installation is carried out immediately after laying heat-insulating materials, on a metal or wooden crate. The undoubted advantage of the material is a huge selection of colors, patterns and combinations, as well as high strength. It also has disadvantages - high thermal conductivity and low sound insulation.

Vinyl siding or PVC panels are a popular and sought-after finishing material, which is characterized by low cost and long term operation. PVC siding from a reliable manufacturer will surely serve you for 50 years, it is not afraid of corrosion, it is not afraid of aggressive substances. The huge color scale will satisfy the most exacting buyer.

A big plus of vinyl is its lightness, which makes it possible to use the material for finishing buildings, the foundation of which is not designed for heavy loads. In addition, you get a ventilated facade, which eliminates the appearance of condensation on the thermal insulation and wooden frame elements. This material does not interest insect pests at all. As for fire safety - polyvinyl chloride does not support combustion. If there is no open source of fire nearby, the melted panels quickly die out.

Builders love it for its simplicity and ease of installation, customers give preference to panels, because this deprives themselves of the extra hassle of caring for the facade. It can be washed with plain water from a hose or use soap solutions. What can be blamed for PVC siding is its unnaturalness - supporters of environmentally friendly materials often and unreasonably accuse the material of releasing toxic substances into the air when heated and burned.

However, this statement is quite far from the truth - only panels made from recycled materials can be harmful. They are cheap and have a short lifespan. Outwardly, low-quality panels can be distinguished by the yellow color of the draft side. Polyvinyl chloride, made from virgin raw materials, has an exceptionally white color.

3 Heavy but durable – alternative finishes

Builders and customers much less often give preference to these finishing materials, which to some extent becomes their advantage - frame houses look more original, become like heavy structures made of stone and brick. We deservedly give the first place in the list of alternative finishes to natural stone - this finishing material was used back in the era of the construction of aristocratic castles.

The stone is highly durable, but it’s not worth talking about durability. Of course, at facing stone large weight and thickness, it is not as easy to use as fitted and identical siding, has a high cost and a rather limited color range. However, it is not at all necessary to use it for finishing the entire house - often natural stone serves as an addition to plastering, it is used to decorate the plinth or near-window space.

Artificial stone - the material is more affordable and easy to use. It differs from the previous version in a large selection of colors, as well as less weight. Artificial stone improves the thermal insulation of the house, even a novice builder can work with it. However, the exterior decoration of a frame house with stone, albeit artificial, creates too much load on the foundation and walls, so the bearing capacity of the foundation should be carefully calculated.

Decorative plasters are more popular - this type of finish has many application technologies and a wide range of colors. Plaster is often used when foam is used as a heater - it can be applied directly to polystyrene foam. With their help, you can hide small irregularities or defects, at a price they are quite affordable for every construction budget.

Marble chips - a modern version of plaster. The crumb is mixed with silicone and acrylic, due to which the finish acquires excellent protective qualities, is not afraid of frost and moisture. Marble crumb creates a unique texture of the facade, in addition, it allows the walls to "breathe". The material is fire resistant and retains heat well. Its main drawback is its high cost.

Facade tiles and bricks are elite materials for finishing frame houses. They are distinguished by their aesthetic appearance, they create additional heat and sound insulation and serve for an unusually long time - with proper installation, facade repairs will be needed no earlier than after a good hundred years. Working with them is quite simple, but such a finish is very expensive.

The times when wood was considered a warm material have sunk into oblivion. To prevent heat transfer through a wooden wall, its thickness must be at least 530 mm. for central Russia. The frames of individual houses are made mainly of wood, and sometimes metal structures are used, which makes the problem even more acute.

Therefore, the exterior finish of a frame house, in addition to purely aesthetic, often performs an important technological function - it insulates the wood (or metal) of the frame, which itself serves as a cold bridge. Of course, in this article we will also consider finishing options that ignore this fact, but we have no right not to mention it.

What is the frame house trimmed with?

There are no special restrictions on the exterior decoration of a frame house, there are some features of the use of one or another of its types, which we will inform you about. Frame houses are faced with:

- brick;

- tree;

- vinyl siding;

- thermal panels;

with the device of the "wet facade" system,

- plaster;

- color;

- apply polymeric coatings.

You must make a decision about this or that type of exterior decoration of the house at the stage of its design, since some of them begin already at the stage of laying the foundation.

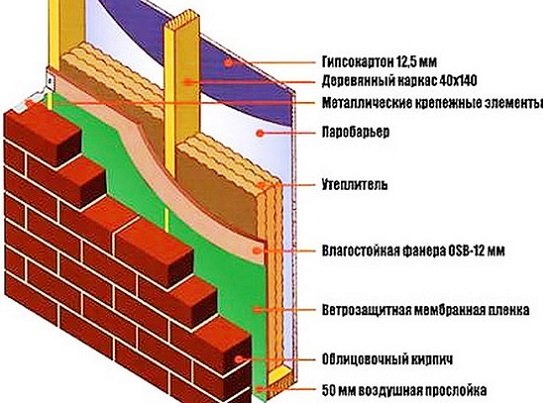

Facing a frame house with bricks

If you have decided that your frame house should look brick outwardly, then one of the options is to overlay it with natural bricks. The main requirement in this case is the presence of a gap of 30 - 50 mm between the wall of the house and the inside of the brickwork and ventilation holes that ensure air circulation in this gap.

If this is not done, then moisture will inevitably condense on the inner surface of the brick during the cold season, which will ultimately lead to its accelerated destruction. She will also not spare the outer enclosing material of the frame itself, which is most often OSB or plywood.

Naturally, both the width and the bearing capacity of the foundation with this type of finish are adjusted upwards. In general, these are two different systems of housing construction, and when combining them, you should try to avoid rigid ties between the frame that does not shrink and the brick coat that shrinks during the year. The consequences can be dire.

This can be disguised by a lowered roof overhang that does not connect to brickwork. Also, either postpone for a while the manufacture of external window and door slopes, or do not make their connection with the masonry rigid. It can be metal or plastic corners.

Wood frame house cladding

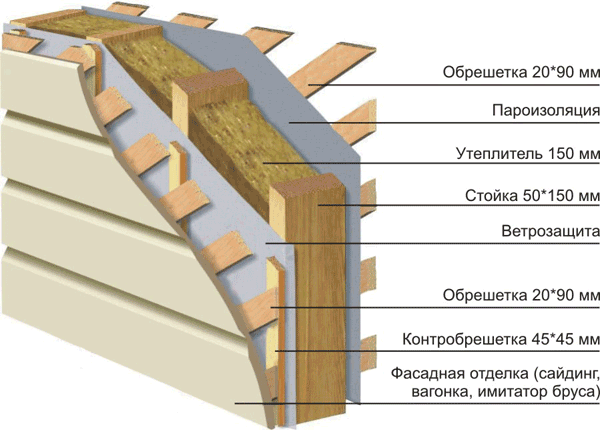

Proper cladding with wooden moldings, such as a block house, false timber, etc., will give your home a stylish look. Using them can also eliminate the outer sheathing of OSB, plywood or other board material from the wall pie.

A well-dried and treated with the necessary impregnations, a textured wooden beam can be directly attached to the racks of the house frame from the inside, before laying a layer of insulation, as well as on clamps or through self-tapping screws - after it. Keeping in mind that a tree can be a bridge of cold, we can recommend such fastening in case of erection of a double frame, with the racks shifted relative to each other.

Also, finishing the frame with wooden elements can be done along the crate with a ventilation gap. It is important to remember that such a facade of your house will require periodic maintenance, which consists in timely processing with coloring and impregnating materials. And, of course, the tree will crack somewhere, somewhere on the sunny side the gap in the joints will increase. You just need to be prepared for this when choosing this option for exterior decoration of the house.

Composite materials that have appeared recently in a large assortment that imitate the structure of wood are completely devoid of these shortcomings, but those who are ready to shell out a fairly large amount for their purchase will be able to verify this.

Exterior siding

This is the easiest option for finishing a frame house. If you have OSB or plywood on the outside of your house, you can simply attach strips of vinyl or basement siding cards to them. These materials practically do not change their geometry when exposed to heat and cold, the siding itself will protect them from water, so you can not look for complicated and expensive ways to find beauty in your home. They also hold screws well.

The choice of a columnar-beam version of the frame allows you not to use OSB outer skin or other materials at all, but to fasten the siding directly to the frame posts.

If you want to thermally insulate the frame tree, then mount the siding on remote vertical rails screwed to the horizontal crate with a shift from the main frame beams and filling the gap between them with insulation.

At the same time, it is important not to forget that outside the wall there should be a heater with a greater thermal insulation capacity, or the same as used in the wall pie, in order to avoid moisture condensation at the boundary of the materials.

This type of decoration makes the house even more maintainable than it is assembled using technology, finished with other types of materials.

In addition to plastic siding, metal siding can be used, but more often it is placed on non-residential buildings.

Finishing a frame house with thermal panels

Thermal panels are different. By dimensions, by materials, by type and method of fastening. But one thing unites them: the presence of a layer of insulation and an outer finishing layer. Insulation can be polyurethane foam, expanded polystyrene, dense basalt.

Outside it can be: clinker tiles or clinker bricks, a thin polymer concrete slab that imitates various natural finishing materials. This layer can be painted in mass or require painting after installation and grouting. There are a lot of options for the execution of thermal panels, you will always find several in your region to choose from.

This type of exterior finish, in addition, radically solves the problem of thermal insulation of the frame. The only thing we recommend in this case is to glue the panels on polyurethane foam glue or polyurethane mounting foam with the maximum filling of the contact area with the wall.

Wet facade on a frame house

The “wet facade” technology is not so much different in execution for frame structures, as it has some features. Namely, it's not worth it:

- glue polystyrene foam or basalt on cement mixtures to OSB - use polyurethane adhesives or foam;

- use wood screws and either large-diameter plastic washers or fungus caps for fastening - the fungus itself does not hold well in the plate;

The remaining procedures of this technology are common to all types of houses:

- reinforcement with appropriate adhesives with alkali-resistant plastic mesh in 1 or 2 layers;

- primer;

- applying the finishing plaster layer (fur coat, bark beetle, etc.);

- painting.

Plastering the walls of a frame house

When they talk about plastering a frame, they first of all mean plastering OSB. Let's make a reservation right away - this version of the exterior finish can be used either in the case of closing all the seams between the panels with decorative strips (imitation of fachwerk), or as a temporary option for protecting the facade until it is finalized.

No method of sealing the seams will prevent the occurrence of cracks on them. Therefore, choosing this type of finish, do not waste your energy, time, or money on the method described in many articles with gluing sickle, filling with elastic sealants, etc.

Prime the walls with a deep penetration primer, shoot an alkali-resistant mesh with a stapler and plaster with spatulas. It is better to use a special elastic plaster for OSB - several Russian factories already produce this.

Other types of finishing the facade of a frame house

Along with the previous method, other thin-layer coatings for OSB are often used - painting or coating with various polymeric materials with or without the inclusion of fine-grained stone powder.

Obviously, it is necessary to paint with compositions intended for application specifically to OSB. You will find a lot of such materials on the Internet, with their own schemes and laying technologies. Do not experiment with untested materials - it is more expensive for yourself.

The polymer formulations used for application to OSB are either acrylate or polyurethane based. The first ones are less resistant to prolonged exposure to water and, even if dyed in mass, they will serve for a long time with an additional water-repellent outer coating.

Fine-grained quartz is most often used as filling in them. It is more convenient to apply them with a Hopper gun. Polyurethane compounds allow the addition of cement, as a rule, they are applied with spatulas in a sufficiently thick (up to 3 mm) layer. A larger filler can be pressed into them, such as dust-free granotsev or marble chips.

These types of finishes completely hide the structure of the OSB and give a solid look to the house. True, the problem with the seams between the panels can also arise.

Comments:

Each owner dreams of his house standing out from the background of other tasks, having an attractive and unique appearance, so the question of how to sheathe a frame house from the outside will always be relevant. The modern market offers a large selection of materials for finishing a frame house from the outside, so the question arises of how to sheathe a frame house. When making a choice, the preferences of the owner, price, practicality and aesthetics of the material play an important role.

Sheathing a frame house: an overview of materials

The following materials are used to finish the frame house outside.

Wood has always been popular due to the fact that it is natural. Its disadvantage is the high price, so a block house often comes to replace it. This material imitates a natural beam or board and is great for sheathing a frame house.

The advantages of this material:

- high strength indicators;

- good heat and sound insulation;

- the ability to "breathe";

- ease of processing and maintenance;

- the ability to choose any color;

- variety of installation methods.

For sheathing a frame house, a block house made of spruce or pine is used.

It tolerates temperature fluctuations well, goes well with stone and metal, and the fact that it is laid in a continuous sheet prevents cracks from appearing.

wood siding

This material is now almost never used for the outer skin of a frame house. This is due to the fact that it must be constantly treated with an antiseptic, tinted. It absorbs moisture and burns well, so it is replaced with other materials.

Block house

Outwardly, the block house looks like natural wood, but it costs much less and does not crack. Due to the fact that it has a smooth surface, it is possible to finish the frame house with a block house from the outside and from the inside. It is not necessary to glue the wallpaper inside, since this material itself looks spectacular and attractive.

Another advantage of the block house is that you will not only make the frame house more attractive with it, but also insulate it. It has all the benefits of natural wood but is more durable. This material is impregnated with antiseptics and flame retardants at the manufacturing stage, therefore it does not warp or deform, it is not damaged by precipitation and sunlight. Installation of a block house is simple, and almost any home craftsman can sheathe a building with it from the outside.

There are nuances when choosing a block house, which will be used to finish the frame house. If you buy a thin and narrow block house, then from a distance it will look like an ordinary board, which does not look very nice. In order for the frame house to be attractive, it is necessary to take a block house 190 mm wide and 45 mm thick.

You can decorate a frame house with an imitation of timber - so you can get the effect that the house is made of timber, but spend much less money. If the lining can be laid both vertically and horizontally, then the imitation of timber can only be laid horizontally. This material can sheathe a frame house both outside and inside.

Facade tiles

This material allows not only to make the frame house attractive, but also reliably protects it from the effects of negative natural factors.

Natural finishing stone

The disadvantages of natural stone for building cladding is that it has an arbitrary thickness and dimensions, and this greatly complicates its installation.

It is not presented in a wide range of colors, it has a lot of weight, so it is almost never used for finishing a frame house.

Stone is a fairly expensive material, and few people can afford to use it.

Fake diamond

It has a more varied palette and less weight. Those who have an idea how to lay ceramic tiles will be able to work with artificial stone without any problems. Artificial stone has good thermal insulation, so the house will be warm and cozy. It is much cheaper than natural stone, so it is more affordable.

Decorative plaster

This material is used quite often for building decoration. With it, you can create a facade that looks like wood, stone, sand or waves. Usage decorative plaster allows you to hide defects and uneven walls.

The composition of the mixture includes silicone, acrylic, marble chips.

The specified material is resistant to moisture and tolerates frost well, so the house will be cozy and comfortable both in winter and in summer. This material retains heat well and does not burn, it is inexpensive and can be used for finishing the building both inside and outside.

The use of siding

The siding differs in low cost, high stability and durability and simplicity of installation. The choice is made between vinyl and metal siding.

Advantages of siding:

- high resistance to elevated temperatures;

- resistance to sunlight;

- high strength.

This material does not retain heat well, therefore, together with it, insulation must be used to sheath the frame house. If applicable metal siding, it is necessary to make a reliable crate, since the material is quite heavy.

metal siding

Siding is very easy to install, as it has special locks and is covered with special paint, so it does not rust and reliably protects the frame house. To decorate the building, you can use panels of different colors.

Vinyl siding

The variety of this material allows you to decorate the house with imitation of any type of wood or stone. Vinyl siding, if properly maintained, will last 50 years or more, won't corrode, and costs less than its metal counterpart. This material is presented in different colors, therefore, for finishing a frame house, you can always choose the desired shade.

Vinyl siding is much lighter than other materials, making it ideal for finishing a frame house. It is not susceptible to mold and rot, it is not damaged by insects, it does not melt or support combustion.

Maintenance of this material is easy, just wash it with soapy water. There is no need to cover it with an antiseptic or periodically tint. If you finished the frame house with vinyl siding, then you will forget about the exterior finish for decades.

In order to prevent cracks and crevices from appearing on the material after finishing the frame house, you must wait until the shrinkage of the building ends.

If the house is sheathed with wood, then the most suitable species are oak and larch. All wooden materials must be further processed to protect them from sunlight, moisture, rot and mold.

To achieve the maximum effect when using lining or siding, it is necessary to additionally install insulation, and mineral wool is the best option.

As you can see, the choice of finishing materials for a frame house is quite large, and you can always choose the material that suits you not only in terms of its qualities and properties, but also in terms of price.

Since the frame house is based on wood, that is, not a very durable option, it is especially important to perform the correct finishing or cladding. With the help of properly selected materials for the facades of frame houses, you can not only decorate the building, but also protect it from external factors - rain, snow, sudden changes in temperature and others. The facade of a frame house can be finished with various materials - from special plaster paints to siding and other panels.

What are developers choosing today?

The choice of materials for cladding depends on the material possibilities and taste preferences. Consider the most popular materials from which the facade of a frame house is made:

- wet facade

- siding

- pvc panels

- block house

- brick or stone

More about finishing materials and exterior decoration can be read.

So, a wet facade is chosen by almost a third of builders. He gained his popularity due to the aesthetic appearance that the house acquires after processing. What is needed for finishing:

- polystyrene or foam boards for additional insulation and surface leveling

- fastening for plates (foam or special reinforcing glue)

- plaster

- primer

- inventory: Valmiera mesh and elements for special fasteners

Finishing takes place in several stages. Among them:

- Preparation of foam boards, cutting, installation and fastening to the facade.

- Application of the first layers of plaster (basic).

- Decorating the last layer of plaster.

With the help of siding, they most often decorate and, buildings for temporary residence, and others. Since frame houses themselves belong to buildings of the middle price category and they are erected, as a rule, by people with average incomes, siding is chosen quite often due to its low price and practicality. It consists of a synthetic material - in other words, plastic. Therefore, bugs, rodents and bacteria do not eat it, fungus or mold rarely form on it, such lining is easy to clean if necessary. PVC siding does not deteriorate, does not change its appearance, and retains its properties for a long time. At the same time, it perfectly protects the walls from moisture, as it does not absorb water and wind (we won’t think it over).

It is also installed quite simply, and its fixation on the facade can be done by hand even without experience. Siding can be attached directly to the OSB boards of a frame house, as it is considered a lightweight material.

Siding belongs to the varieties of PVC panels, but modern panels are still different from simple and inexpensive siding. First of all, fastening.

PVC panels for brick-like facade finishing

The panels are mounted on a pre-installed frame, most often made of metal. Paneling can be installed with or without a ventilating space, which is an air cushion between the panels and the wall. The air cushion makes the house warmer and additionally protects the walls.

Block house for the facade - decorative rolls over

For lovers of natural wood, the construction market offers a block house, a type of facade finish in the form of a wooden bar. The block house completely imitates timber, as a result of which the house acquires a natural and very cozy look. The country house becomes like a hut or a hunting house, and the block house is also used for interior decoration.

In addition to the block house, lining and imitation of timber can be attributed to wooden facades. Their minus is fragility compared to artificial materials and increased fire hazard.

Finishing with stone or brick is the best option, since the stone reliably protects the facade, it looks solid, it is possible to perform decorative masonry, and it also does not burn. However, the price of natural stone and brick is high, and this stops them from being used. Artificial stone is much cheaper, so it has become very popular.

The frame facade can also be plastered or covered with acrylic. Subject to the application technology, this type of finish will last at least 10 years, or even more than 20. At the same time, the number of colors is very diverse, you can use several colors, giving the house a decorative effect and originality.

Deformation: causes and ways to avoid

Sometimes it happens like this: less than two years have passed, and cracks have already begun on the plaster, the customer blames the finisher, and he shrugged his shoulders “not to blame!”. So who is to blame and how to avoid cracks and other deformations in the appearance of the facade? Is it her own fault?

The most common defect in facade decoration is a crack.

Let's figure out where all these damages come from. The frame house is considered the lightest house, which practically does not shrink. As a result, you can choose the easiest and simplest for him. It would seem, why am I talking about this? And to the fact that the choice of foundation affects the shrinkage of the future home. Yes, the frame house is light, but the soils are different. Imagine that the house is standing on wet clay soils. In winter, the water that is in the clay freezes and expands, causing the clay soil layer to rise. Together with it, the foundation also rises, and not evenly. If the foundation is monolithic, then the distortion of the building will be minimal. But for frame houses they often choose. At the same time, the soil cannot be uniform in its composition in different areas. And so we get the rise of one pillar in winter, under which there is more clay and moisture, and some of the pillars can remain at the same level (if there are sandy soils under them). As a result, we get a distortion of the walls, sometimes not visible to the eye, but sufficient for cracks to go along the walls.

That is why new houses in the first five years sometimes have to be plastered, saving the facade from defects. Sooner or later, the house will take a permanent position and cracks will no longer appear.

If the facade was finished with siding, the finish may swell, the siding will rise and bend. This also applies to other methods of facade cladding.

Another reason for the rapid loss of a holistic view of the facade decoration is poor-quality materials from which the frame of the house was assembled. If a wet board was used, over time it changes its volume, twists, and the wall can change its dimensions to some extent. However, such a deformation rarely leads to large gaps, since the OSB board with which the wall is sheathed does not change. But in the corners there may be small defects. Read about the technology for building high-quality frame houses.