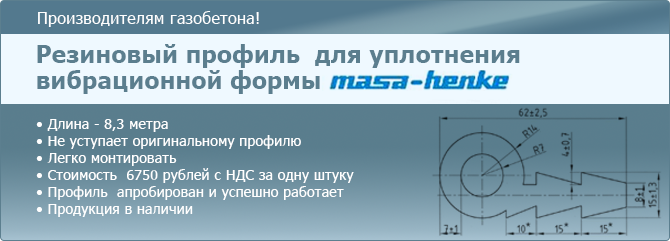

We offer services for the production of a rubber profile for sealing a vibration mold MASA-HENKE (Germany) (article MASA-HENKE - FZ 000000-008889505-A)

Restoration of rollers, shafts, wheels - gumming with polyurethaneRepair of rollers, shafts, wheels.

Restoration of worn coating.

We offer heat-resistant products of the German manufacturer BWF Group for aluminum profile production lines.

Manufacture of hose products from vacuum, silicone and other types of rubber for concrete mortar units, reinforced concrete plants, concrete plants.We offer services for the production of sleeve products from silicone, vacuum, TMKShch, MBS and other types of rubber.

Heat Resistant Universal Silicone Adhesive Sealant RTV118QPrice 890 rubles with VAT per tube

silicone sleevesWe offer services for the production of silicone sleeves suture, seamless. Extrusion. Cold docking.

We offer a rubber profile for various purposes, colors, hardness, configuration. Profile products are produced from rubbers based on natural and synthetic rubbers for general and special purposes: oil-resistant, heat-resistant and weather-resistant rubbers, fluororubber, silicone.

- It is possible to select the rubber compound according to the requirements of the Customer

- Large fleet of dies and molds

- Operational design and production of tooling (dies, molds)

- Sealant docking

- It is possible to manufacture small batches of products

- Provision of samples for testing

- Products are certified

- Delivery within the territory of the Russian Federation

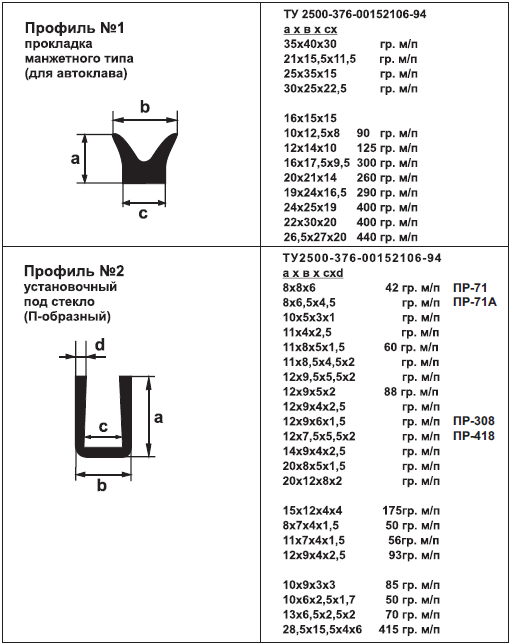

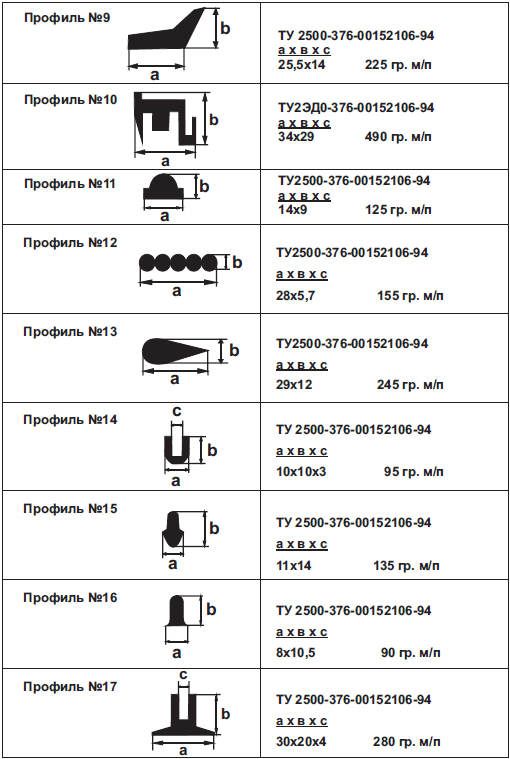

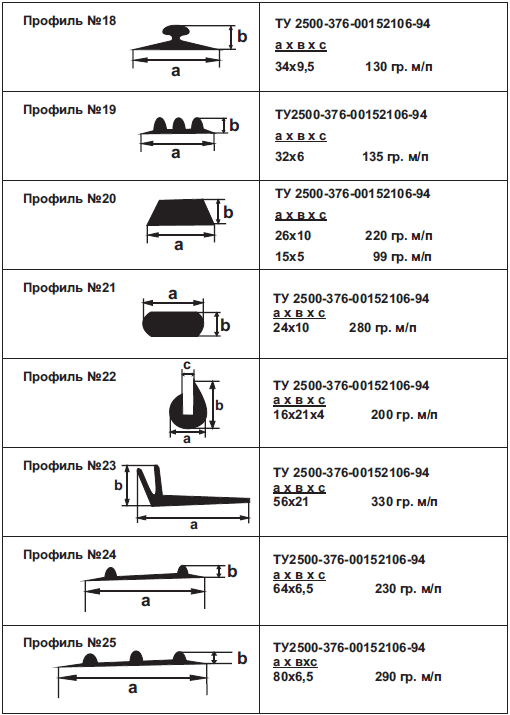

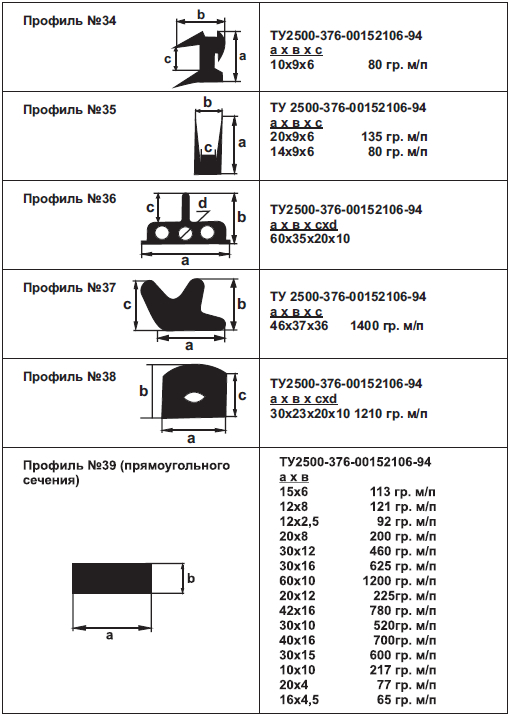

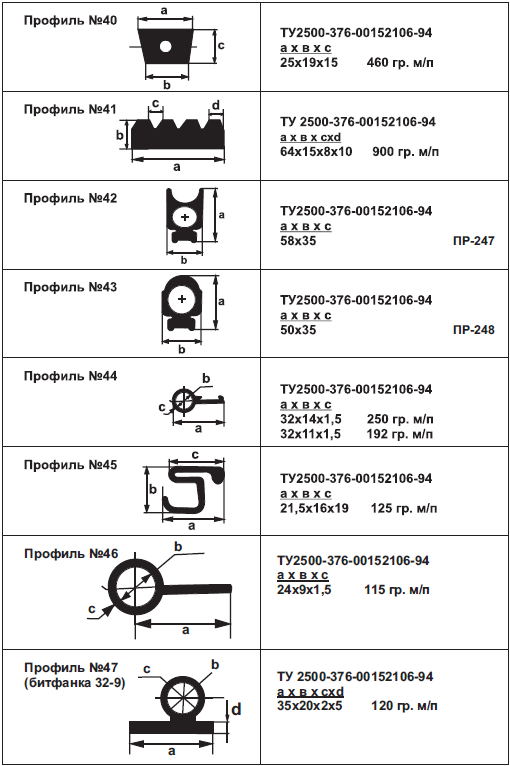

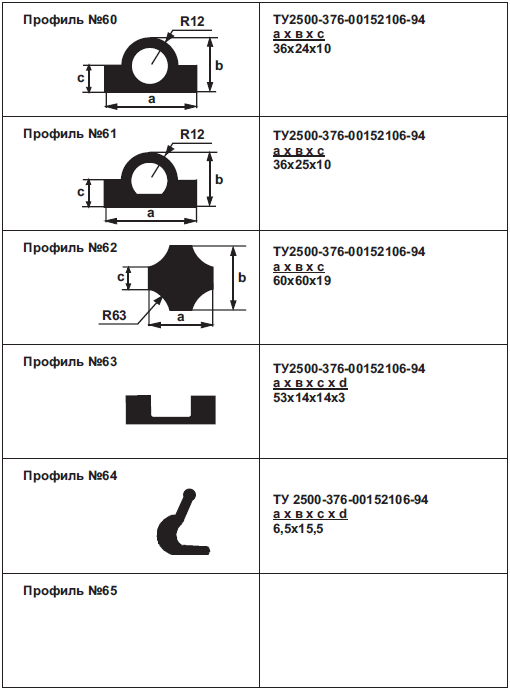

The table shows typical types of rubber profile.

![]()

Rubber profiles are widely used in almost all industries. They are intended for use as sealants for glass and windows of buildings, doors and other elements of car bodies, buses, tractors, harvesters, construction and road machines, refrigerators, food, medical equipment. The rubber profile is used as cushion pads, etc.

Profile rubber products can be conditionally divided into the following groups:

Rubber profile heat and frost acid and alkali resistant (TMKShch)

Oil-resistant rubber profile (MBS)

Rubber profile weatherproof

Rubber profile for working in special conditions. High, low temperatures, contact with food products, aggressive environments. They are made from biologically inert materials based on siloxane rubbers. Silicone profile. Profiles made of rubbers based on fluororubbers, etc.

According to the type of sections, profiled rubber products can be conditionally divided into the following groups:

rubber profile round section.

Rectangular rubber profile

Rubber profile of complex section

Permissible temperature environment, for which a rubber profile can be used, depends on the group of rubbers from which it is made.

The sealant (rubber profile) is transported by any means of transport in conditions that protect against damage in compliance with the rules of transportation established for this type of transport.

To order a rubber profile, send us a sketch or drawing of the seal configuration and working conditions.

It is difficult to overestimate the importance of sealing profiles. They keep the heat in our homes, isolate us from excessive noise, providing comfort and peace in the home. Not a single building structure can do without sealing profiles, but their use is not limited to this.So, for example, in cars, trucks, wagons and other vehicles, you can see seals of various configurations.

Sealing profiles are also used in almost all industrial structures and in all types of industry: oil refining, chemical, mining, engineering, food, medical, etc.

Purpose of rubber profiles and seals

The main purpose of any seal is, of course, the creation of tightness.

But nevertheless, seals can be attributed to specific products, since due to the use in almost all industries, a number of specific requirements are imposed on the material from which the seal is made, such as: oil and gasoline resistance, resistance to multiple reversible deformations, low compression set, high elasticity, light-ozone resistance, resistance to high and (or) low temperatures, etc.

In this regard, sealing profiles are made from the most various kinds elastomeric materials:

Rubbers made from general purpose rubbers: provide high light and ozone resistance and resistance to repeated deformations

Special purpose rubbers: additionally provide oil and petrol resistance, resistance to aggressive environments, resistance to low and high temperatures, incombustibility

Rubbers made of silicone rubber: the profiles of this material remain operational at extremely high temperatures (up to 250 ° C) for a long time.

Fluoro Rubbers: These seals will perform in the most aggressive environments.

A separate modern type of material for the production of sealing profiles are thermoplastic elastomer materials (commonly - TEP, TPE). It should be noted that almost all European manufacturers of seals have completely switched to this type of material. You can learn more about this product from the article Thermoplastic elastomer seals

Specialists of Proekt RTI LLC have the opportunity to manufacture a sealing profile for you from any type of material in accordance with the requirements for its operation! In addition, based on many years of experience in this field, we can provide advice to customers on the choice of material and design of any specific seal. Also, if you do not have product drawings, we can produce any seal according to the attached sample. Specialists of LLC "Project RTI" carry out individual work with each customer in order to find out the optimal ratio "price - quality".

Our advantage is mobility. We are able to respond quickly and flexibly and implement your ideas and always offer the best solutions and prices.

Sealing devices are one of the main elements on which the performance and reliability of hydraulic and pneumatic units and mechanisms depend. At the same time, seals are the weakest link in hydraulic systems, and if it fails, the hydraulic unit becomes inoperable.

O-ring, or sealing ring(English) O-ring) is a type of sealing device made in the form rubber ring

, which is used in technological equipment as a fuse, a seal between metal and other parts. An important part of the gearbox and all connections of technological hydraulic equipment (hoses, and fittings).

O-ring- this is a static (in fixed parts of mechanisms), and under certain conditions, dynamic (with reciprocating, rotational and oscillatory movements) seal.

O-rings (o-ring) are the most common sealing elements for various sectors of industry, they are used for sealing in hydraulic and pneumatic, as well as fuel and lubrication systems.

Rings can be made in any size: with an inner diameter of 1 mm to 2000 mm and cross-sectional diameters of 0.5 mm to 20 mm.

Rings are made in various sizes from various materials of various types and hardness. O-ring search carried out according to its designation:

For example: 010-014-25-2-2

The first three digits (010) indicate the diameter of the surface on which the ring (rod) is put on - 10mm.

The second three digits (014) indicate the diameter of the surface into which the ring (cylinder) is inserted - 14mm.

The next two digits (25) indicate the cross-sectional diameter (thickness) of the ring itself - 2.5 mm.

The last two digits: 2 - accuracy class, 2 - rubber group. So, real rubber ring size may slightly differ from the designation: internal downwards, external vice versa - increase. Designation: 010-014-25, size: 9.7x14.7x2.5mm.

Applicability from -60 to +250С° depending on the rubber group.

The designation of imported rings differs from the designation of domestic ones.

For example: 005.0x1.0, where 005.0 is the actual inner size of the ring, and 1.0 is its thickness. Imported O-rings are made from four types of material:

- 72 NBR - mineral oils, hydraulic fluids based on mineral oils, static pressures up to 100 atmospheres, temperature conditions from -30° to +100° С;

- 88 NBR - for higher pressures, temperature range from -30° to +100° С;

- FKM - for chemically aggressive media and high temperatures, -20° +200° С;

- EPDM - for hydraulic fluids based on glycol, brake fluid, hot water, temperature range from -50° to +150° C. Domestic rings are made from 7-B-14 rubber compound. Temperature range from -50° to +100° С

- O-rings are manufactured in accordance with

the following standards:

O-rings GOST 18829-73

Rubber sealing rings of round section GOST 9833-73

International o-ring standard DIN 3771

Rubber compounds based on imported rubbers are used as materials in the production of sealing rings:

acrylonitrile butadiene rubber (NBR),

fluorine-filled Viton rubbers and rubber compounds based on them FKM, FPM,

ethylene propylene diene rubbers (EPDM),

silicone rubbers (silicone - VMQ),

polyurethanes (PUR, TPU).

Thanks to modern production technologies and the use of high quality materials (mostly imported), o-rings (o-rings) can be used in media such as various oils, hydraulic fluids, various chemically aggressive media, glycol-based brake fluids, hot water. At various pressures and operating temperatures.

Benefits of using as O-ring seals:

simple design of the mounting cavity (groove),

wide range of materials available: NBR, FPM, EPDM rubber, silicone, polyurethane,

easy installation due to symmetry,

small seat size.

Material

| Material | Designation | Hardness | Colour | Temperature |

| 70 NBR 33002 | Acrylonitrile butadiene rubber | 70 Shore A | the black | -20 °C … +100 °C |

| 90 NBR 33004 | Acrylonitrile butadiene rubber | 90 Shore A | the black | -20 °C … +100 °C |

| 80 FKM 33034 | Fluor rubber | 80 Shore A | the black | -20 °C … +200 °C |

| 70 EPDM 33022 | Ethylene propylene diene rubber | 70 Shore A | the black | -40 °C … +150 °C |

| 70 VMQ 33042 | Vinyl methyl polysiloxane | 70 Shore A | red | -40 °C … +225 °C |

EPDM (Ethylene Propylene Diene Rubber)

Fittings and sealing elements made of EPDM are mainly used in washing machines, dishwashers and water valves. EPDM elastomers have very good resistance to ozone, aging and atmospheric conditions. Good swelling resistance hot water, steam, washing liquor, oxidizing media, acids, bases, polar organic media, ketones, flame retardant hydraulic fluids of the HFC group and some types of the HFD group, glycol ether brake fluids. High swelling capacity in mineral oils and greases, gasolines, as well as aliphatic, aromatic and chlorinated hydrocarbons. Application temperature range: approx. -40 °C to +150 °C.

FKM (Fluoro rubber)

FKM-based materials have gained particular importance due to their thermal stability and chemical resistance. The gas permeability of these materials is low. Under high vacuum, FKM elastomers offer minimal weight loss. High resistance to ozone, weathering and light cracking and flame propagation. Good swelling resistance in mineral oils and greases (also with most additives), fuels, aliphatic and aromatic hydrocarbons, some flame-retardant hydraulic fluids and synthetic aircraft engine oils. High swelling capacity in polar solvents and ketones, flame retardant hydraulic fluids such as skydrol, glycol ether based brake fluids. Application temperature range: approx. -20 °C to +230 °C.

NBR (Acrylonitrile Butadiene Rubber)

It is a polymer of butadiene and acrylonitrile. O-Rings are produced in a wide range of sizes based on NBR material. Good swelling resistance in aliphatic hydrocarbons, e.g. propane, butane, gasoline, mineral oils (lubricating oils, hydraulic oils of groups H, H-L and H-LP) and mineral-based greases, flame retardant fluids of groups HFA, HFB and HFC, vegetable and animal oils and fats, light diesel fuel and diesel fuel. Medium swelling resistance in fuels with a high aromatic content (super brand fuel). High swelling capacity in aromatic hydrocarbons, e.g. benzene, chlorinated hydrocarbons, e.g. trichlorethylene, flame retardant hydraulic fluids of the HFD group, ethers, polar solvents, and brake fluids based on glycol ether. Temperature range of application depending on the burning of the mixture: from about -30 °C to +120 °C.

Silicone rubber VMQ (Vinyl Methyl Polysiloxane)

O-Rings are especially characterized by high temperature resistance, good elasticity at low temperatures, high dielectric properties, high resistance to oxidation and ozone attack and, above all, physical properties, which depend very little on temperature. Medium swelling resistance in mineral oils (comparable to CR based materials) and glycol ether based brake fluids. Can be used in water up to approx. +100 °C. Sufficient stability in aqueous solutions of salts, in mono- and polyalcohols. High swelling capacity in simple and complex low molecular weight ethers, aliphatic and aromatic hydrocarbons. Concentrated acids and alkalis, water and steam at temperatures above 100 °C are destructive to the material. Application temperature range: approx. -60 °C to +225 °C.

are made from rubber (NBR, FPM, MVQ), fluoroplast (PTFE) and polyurethanes (PUR).

Depending on the material used, they are used in environments such as:

acids, alkalis and bases

ketones and alcohols

salt solutions

aromatic hydrocarbons

organic and inorganic solvents

air in pneumatic systems

water vapor.

The operating temperature range also depends on the material used and can be from -60°С to +200°С

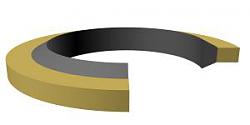

O-rings of square and rectangular sections designed to prevent leaks and protect against dust, dirt and moisture in open flanged joints and fittings, plane-parallel and semi-nested fixed flanged joints in connecting parts of pipelines. Usually used in static nodes, but can also work with dynamics.

Node sealing rectangular rings at low operating pressure, it is achieved by pre-compression of the ring during assembly of the sealed unit, the recommended radial compression of the ring is 0.1-0.2 mm. The tightness of the connection is ensured by the displacement of the ring under the pressure of the working medium. The dimensions of the rings and grooves for their installation are selected based on the provision of a lateral clearance in the range of 0.2-0.25 mm when assembling the ring (without compression). To reduce the friction force of the rings in a number of designs, it is possible to reduce the sealing area in contact with the sealing surface, this is achieved by chamfering, which also increases the service life of the rings at operating pressures up to 1.0 MPa

Same rectangular rings have been widely used as support rings, which serve to protect seals (mainly during the dynamic operation of the sealed assembly), that is, they themselves do not serve as a seal - they are used to prevent the seal from being forced into the rod / cylinder gap. They are made from materials with greater hardness and strength (for example, PTFE) than the material of the protected seal.

They have an annular shape with a rectangular, less often shaped, cross section. They can be made cut (straight cut or at an angle). The height of the ring is equal to the depth of the seal mounting groove plus the height of the stem/cylinder gap. Depending on the direction of pressure, the seal is protected by one or two back-up rings.

Rectangular rings can be an integral part of other seals and serve to reinforce them under particularly heavy loads.

The dimensions of the rings are indicated as follows: d x D x h, where d is the rod diameter (mm); D - cylinder diameter (mm); h is the height of the ring.

Example symbol: 25x35x10, where 25 - rod diameter, mm; 35 - cylinder diameter, mm; 10 - ring height, mm

Regulatory documents: GOST 15180-86 Flat elastic gaskets. Basic parameters and dimensions.

Selection of rectangular rings carried out depending on the characteristics of the medium in contact with the ring and the technical parameters of the equipment.

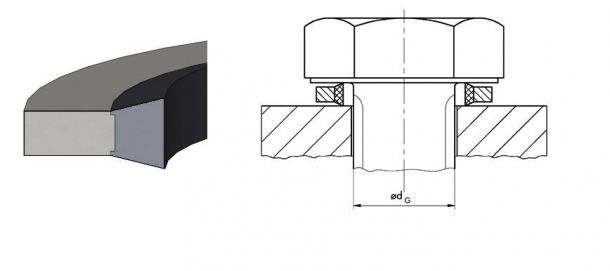

Rubber-metal self-centering seals USIT-R/M.

USIT-R/M rubber self-centering seals are a combination of a metal washer and an elastomeric sealing lip. Rubber metal self-centering seals are a rational development of traditional sealing washers and copper rings, aluminum (copper or aluminum gaskets) or other deformable materials and allow the sealing of liquids at pressures up to 700 bar. Unlike other types, rubber-metal gaskets have significant technical and economic advantages, the main of which are:

High adhesion efficiency of rubber-metal washers even in the presence of small displacements between metal planes as a result of elastic deformation caused by the pressure of the medium;

The tightening torque of the rubber-metal sealing ring is significantly lower than that required for copper and aluminum seals and eliminates the risk of deformation of the surfaces to be mounted;

Reducing the risk of weakening in case of vibrations;

Possibility of contacting parts under conditions of less precise surface treatment for very high pressure, which is more cost-effective;

Reusability rubber-metal ring, even after frequent dismantling (metal washers should normally be replaced after the first dismantling).

With the appearance on the market rubber-metal seals have found a wide range of applications and are now being used not only for the most severe applications requiring first-class sealing and long-term safety, but also for serial components produced in large quantities, for example, in the automotive industry.

Rubber-metal gaskets are manufactured in various versions for industry and aviation. Seals standard type are suitable for the most common industrial applications.

Technical data:

The maximum pressure that the sealing ring resists depends on the size and version and ranges from 25 to 70 MPa.

Operating temperature: -30 °C to + 200 °C.

Media: mineral oils, synthetic oils, water, water-oil emulsions, gases.

|

|

| Ordering name | Size rings | Min pressure gap |

||||||

|---|---|---|---|---|---|---|---|---|

| Tolerances, mm: — > |

0,13/ |

0,1/ |

0,1/ |

0,25/ |

0,1/ |

0/ | (bar) | |

| USIT-R1/8" | 1/8" | 15,88 | 11,84 | 10,37 | 0,25 | 2,1 | 8,56 | 1500 |

| USIT-R1/4" | 1/4" | 20,57 | 15,21 | 13,74 | 0,25 | 2,1 | 11,45 | 1550 |

| USIT-R3/8" | 3/8" | 23,8 | 18,75 | 17,28 | 0,25 | 2,1 | 14,96 | 1260 |

| USIT-R1/2" | 1/2" | 28,58 | 23,01 | 21,54 | 0,25 | 2,1 | 18,64 | 1150 |

| USIT-R5/8" | 5/8" | 31,75 | 24,97 | 23,49 | 0,25 | 2,5 | 20,60 | 1250 |

| USIT-R3/4" | 3/4" | 34,93 | 28,53 | 27,05 | 0,25 | 2,1 | 24,13 | 1060 |

| USIT-R 1" | 1" | 36,88 | 33,89 | 33,89 | 0,25 | 2,5 | 30,3 | 870 |

| USIT-R1.1/4" | 1.1/4" | 52,38 | 45,93 | 42,93 | 0,25 | 2,5 | 38,96 | 690 |

| USIT-R1.1/2" | 1.1/2" | 58,60 | 51,39 | 48,44 | 0,25 | 2,5 | 44,86 | 690 |

| USIT-R 2" | 2" | 73,03 | 63,63 | 60,58 | 0,25 | 2,5 | 56,67 | 700 |

| USIT-M4 | M4 | 7 | 5,4 | 4,5 | 0,3 | 1 | 3,4 | 1770 |

| USIT-M6 | M6 | 11 | 8 | 6,6 | 0,3 | 1 | 4,7 | 1680 |

| USIT-M8 | M8 | 14 | 10,4 | 8,7 | 0,3 | 1 | 6,4 | 1550 |

| USIT-M10 | M10 | 16 | 12,4 | 10,7 | 0,4 | 1,5 | 8,56 | 1350 |

| USIT-M12 | M12 | 18 | 14,4 | 12,7 | 0,4 | 1,5 | 9,73 | 1250 |

| USIT-M14 | M14 | 22 | 16,4 | 14,7 | 0,4 | 1,5 | 11,38 | 1510 |

| USIT-M16 | M16 | 24 | 18,4 | 16,7 | 0,4 | 1,5 | 13,41 | 1400 |

| USIT-M18 | M18 | 26 | 20,44 | 18,7 | 0,4 | 1,5 | 14,76 | 1275 |

| USIT-M20 | M20 | 28 | 22,5 | 20,7 | 0,4 | 1,5 | 16,76 | 1150 |

| USIT-M22 | M22 | 30 | 24,4 | 22,7 | 0,4 | 2 | 18,74 | 1100 |

| USIT-M24 | M24 | 32 | 26,4 | 24,7 | 0,4 | 2 | 20,11 | 1050 |

| USIT-M26 | M26 | 35 | 28,4 | 26,7 | 0,4 | 2 | 22,3 | 1050 |

| USIT-M27 | M27 | 36 | 29,4 | 27,7 | 0,4 | 2 | 23,3 | 1060 |

| USIT-M30 | M30 | 39 | 32,7 | 31 | 0,4 | 2 | 25,7 | 860 |

| USIT-M33 | M33 | 42 | 35,4 | 33,7 | 0,4 | 2 | 28,7 | 820 |

| USIT-M36 | M36 | 46 | 38,4 | 36,7 | 0,4 | 2 | 31,1 | 760 |

| USIT-M42 | M42 | 53 | 44,4 | 42,7 | 0,4 | 2 | 36,5 | 690 |

1 860,00

Rub. / whip

Article: U-902010

Profile width - 86 mm;

Profile length - 2550 mm.

Material - frost-resistant and oil-resistant rubber. Mounted on the doors of refrigerated vehicles to seal the doorway. During installation, an aluminum pressure plate is required, which, using rivets or self-tapping screws, fixes the sealing profile in right place. Mounting plate code - P-909120 (supplied separately).

1 590,00

Rub. / whip

Article: U-902011

Profile sealing rubber for back and lateral doors of the automobile cargo van Bychok.

Profile width - 50 mm;

Profile length - 2550 mm.

Material - frost-resistant and oil-resistant rubber. Mounted on car doors Bull for sealing the doorway. During installation, an aluminum pressure plate is required, which, using rivets or self-tapping screws, fixes the sealing profile in the right place. Mounting plate code - P-909123 (supplied separately).

1 480,00

Rub. / whip

Article: U-902012

Rubber sealing profile for the rear and side doors of the Gazelle cargo van.

Profile width - 40 mm;

Profile length - 2550 mm.

Material - frost-resistant and oil-resistant rubber. It is installed on the doors of GAZEL cars to seal the doorway. During installation, an aluminum pressure plate is required, which, using rivets or self-tapping screws, fixes the sealing profile in the right place. Mounting plate code - P-909122 (supplied separately).

1 680,00

Rub. / whip

Rubber seal for van/sea container door

Article: U-902013

Rubber sealing profile for the rear and side doors of a car cargo van and container of the "Morflot" type.

Profile width - 37 mm;

Profile length - 2400 mm.

Material - frost-resistant and oil-resistant rubber. Installed on the door automobile cargo van and container type "Morflot" for sealing a doorway. During installation, an aluminum pressure plate is required, which, using rivets or self-tapping screws, fixes the sealing profile in the right place. Mounting plate code - P-909121 (supplied separately).

1 795,00

Rub. / whip

Article: U-902014

Rubber sealing profile for rear and side doors of automobile cargo van and refrigerator.

Profile width - 63 mm;

Profile length - 2550 mm.

Material - frost-resistant m oil-resistant rubber. Mounted on the doors of refrigerated vehicles to seal the doorway. During installation, an aluminum pressure plate is required, which, using rivets or self-tapping screws, fixes the sealing profile in the right place. Mounting plate code - P-909120 (supplied separately).

1 465,00

Rub. / whip

Rubber seal for the door of manufactured goods van

Article: U-902015

Rubber sealing profile for rear and side doors of automobile freight manufactured goods van.

Profile width - 28 mm;

Profile length - 2550 mm.

Material - frost-resistant and oil-resistant rubber. Is established on a door of a manufactured goods van for sealing of a doorway. During installation, an aluminum pressure plate is required, which, using rivets or self-tapping screws, fixes the sealing profile in the right place. Mounting plate code - P-909121 (supplied separately).

1 465,00

Rub. / whip

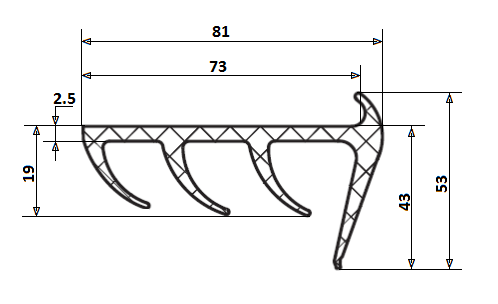

Article: U-902016

Rubber sealing profile for rear and side doors of automobile thermally insulated van.

Profile width - 81 mm;

Profile length - 2550 mm.

Material - frost-resistant and oil-resistant rubber. Mounted on the door of a thermally insulated van to seal the doorway. During installation, an aluminum pressure plate is required, which, using rivets or self-tapping screws, fixes the sealing profile in the right place. Mounting plate code - P-909121 (supplied separately).